Industrial MSW Waste Recycling Machine

Shredder Machine, Conveyor Machine, Incinerator Machine, Briquette Machine

The world shifting towards “Green Living” recycling equipments is more in demand than ever across many industries that work with waste material for all types of application, instead of throwing away the materials, these products can be shredded, screened, melted are re purposed for different end products. Recycling materials is imperative in today’s global climate.

We design and represent with after sales support of recycling system has the recycling equipment’s needed to reduce any company’s ecological footprints.

There are many types of recycling equipment’s which reprocess waste materials and make the materials reusable for another product. We have all machinery available like Shredding, Screening, Grinding, Sorting, Separation, Pelletizing and more….

Products Application:

- Muncipal Solid Waste MSW RDF

- Cable Recycling

- Single Shaft Shredder

- Wood, Plastic, Metal,

- Rubbers

- Shredder Industrial Waste Chemicals

- Food Waste

- Textile, Cardboards, Papers Mining

- E-Waste

- C&D Automobile Furniture

Machine Types:

- MSW & RDF Wastes Recycling

- Paper & Cardboard Waste Recycling

- E-Waste Recycling Machine

- Hazarous Waste Recycling Machine

- Metal Recycling Machine

- Plastics Recycling Machine

- Wood Recycling Machine

- Tyre Recycling Machine

TYPES OF SHREDDING MACHINES

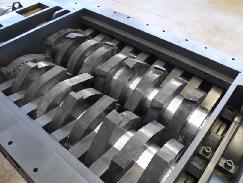

Dual Shaft Shredder Machine

Dual shaft shredder have been designed for a wide array of application and industries, suitable for shredding solid material such as e-waste, wood, plastic, scrap tires, etc.

Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction. It is widely used in industry waste recycling, tire recycling, plastic recycling, electronic recycling, municipal solid waste recycling and more..

Advantages

- Alloy Steel Cutters & Shafts

- In-Feed & Discharge Conveyors

- Anti Jam Auto Reverse

- Flow Speed High Torque

- Low Noise

- Electric Or Hydraulic Drives

- Different Cutter Profiles

- Custom Stand & Hoppers

Industrial needs

- Muncipal Solid Waste

- Wood, Plastic, Metal,

- E-Waste, Food Waste

- Rubbers, Cable Recycling

- Textile Cardboards Papers Mining

- C&D Automobile

- Furniture Single Shaft Shredder, Industrial Waste Chemicals

- Telephone Interference

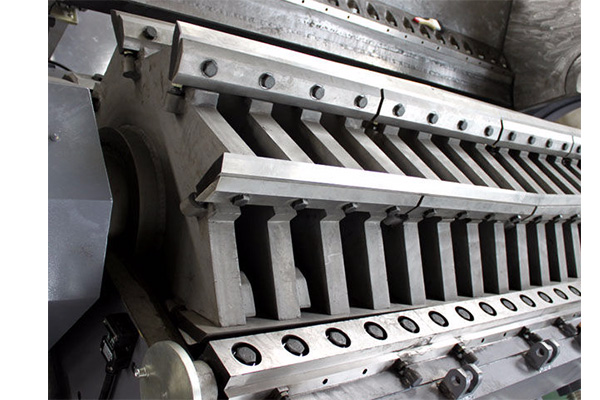

Single Shaft Shredder Machine

Series single shaft shredders are specifically developed for the side reduction of different plastic scarps-pieces and wood, paper, cables, light alloy pieces purges, films and car components these single shaft shredders are also suitable for electric cables, wood, paper and offers energy savings.

Trommel Screen Machines: Solid Wastes Recovery Of Valuable Minerals

Trommel Screens can be used in a variety of applications such as classification of solid waste and recovery of valuable minerals from raw materials.

Grinding Machines: Hammer Mill

- Hammer mill feeding material is impacted by the hammer bars and is thereby shredded and expelled through screens in the drum of a selected size.

- The hammer mill can be used a primary, secondary, or tertiary crusher.

Granulator Machine

- Single shaft shredders are specifically developed for the side reduction of different plastic scarps-pieces and wood, paper, cables, light alloy pieces and much more and offers energy-savings. Suitable for the recycling of any plastic parts, purges, films and car components.

- These single shaft shredders are also suitable for electric cables, wood, paper, etc.

Chipper Machine

Industrial Applications

- Agriculture

- MSW / RDF Waste Recycling Process

- Plastics Recycling

- Rubber Recycling

- Food Processing Waste Recycling

- Minerals And Chemical

- E-Waste Recycle

- Automobile Waste Recycle

- Parmaceutical Waste Recycle

- Woods Chipper Recycle

- Composting Machine

- Paper And Cardboards Recycle Process

INCINERATORS A FUEL FREE SOLID WASTE MANAGEMENT PLANT

- Our Modern Incinerator is a furnace for burning waste with advanced Air Pollution control System. Many paper and pulp mills incorporate them into their pollution mitigation systems. Incineration involves the high-efficiency combustion of certain solid, liquid, or gaseous wastes.

- Garbage’s & Food Industry wastes are properly shredded is loaded in the Incinerator primary chamber. A piece of paper ignited is inserted to the chamber and ensuring the Fire has spread over the garbage / wastes , Burning will be raised and spread up full strength within 2 minutes and temperature inside the chamber will shoot up in 5 minutes above 900 deg c.

- The high hot flame will enter to the specially designed secondary chamber through natural draft in proportion to the velocity of hot air and by heat concentration technique the temperature of the flame will be over 1300 deg C. The exhaust will get a residence time of 3 sec in this chamber.

- The emissions from the secondary chamber will directly enter the Air pollution control Attachment ( Wed Scrubber Unit ) it passes through misty spray of water and steam. The particulars and other hazardous emissions will be cleaned inside the scrubber unit and air pollution will be minimal. The drain from wed scrubber can be recycled by connection to the inlet of STP or ETP.

- The output water for STP or ETP can be reused again to input of incinerator scrubber feeding water.

ADVANTAGES OF WASTE INCINERATORS

- Decreases Quantity of Waste

- Efficient Waste Management

- Production of Heat and Power

- Compact Size Occupies Small Space

- Incinerators Operate in Any Weather

- Reduction of Pollution

- Incinerators Have Advanced Scrubber Filters For Trapping Pollutants

- Saves on Transportation of Waste

- Effective Metal Recycling

- Compact Size Occupies Small Space

- Provides Better Control Over Odor and Noise

- Prevents the Production of Methane Gas

- Eliminates Harmful Germs and Chemicals

- Uses of Ash

- Uncontaminated Groundwater

Conveyors ( belt conveyor / chain conveyor / bucket elevators )

Conveyors are the basic tools in material handling industry, belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys (a.k.a. drums). An endless loop of carrying medium—the conveyor belt— rotates about them.

Sample Videos

solid waste pelleting machine (briqutte machine)

- We Manufacturer of a wide range of products which include MSW/RDF pellet making machine.

- The briquette working process is in a chamber where materials are fed into, there materials are briquetting under a very high pressure. It causes their plasticity and makes them binding stably together as a block.

- Briquetting machine is also called RDF Pellet making machine , Briquetting press machine, Briquette making machine or Briquette maker, etc. It is a machine that is used to process biomass raw materials into high-density wood briquettes, sawdust briquettes or charcoal briquettes with the shape of blocks or rods.

- Production Capacity: 50 – 2000 Kg/hr

- Fast and Door Step Delivery , Lifetime Maintenance, Over 25+ years experience, low noise, Compact Design . Prompt after Sale Support.. 100% Customer Satisfaction.

- Machine Types: Balers, Briquetting Presses